High torque drive timing belts or HTD timing belts are the belts used to provide high-power transmission and control of motion of applications. These are the most widely spread used belts in industries. These belts provide the economic solution in the lower and high range of performance.

The HTD timing belts are the type of toothed belts that are designed to transmit high levels of torque between drives and driven parts. Their different trapezoidal tooth sets them apart from other belts.

Key features and applications of HTD belts

High Torque

HTD timing belts are specially manufactured to bear high torque loads, making these belts suitable for high-demand power transmission requirement applications. This feature of HTD belts makes them useful for heavy machinery in industries.

Noise reduction

Some applications are run at places where too much noise is a problem. These HTD belts are best for applications where noise reduction is compulsory because their special tooth profile makes the quitter operation as compared to other tooth profile belts.

Reduced Backlash

The trapezoidal tooth shape reduces backlash or the clearance between the teeth of the belt and the pulley, resulting in improved precision and accuracy in positioning and motion control applications.

Wide Range of Sizes

Various sizes, widths, and pitches are available in HTD timing belts to accommodate a broad spectrum of applications. This versatility makes them suitable for various industries and uses.

High power efficiency

These belts are especially known for their high power efficiency. The efficiency in power transmission helos to minimize energy loss and maintain high transmission efficiency.

HTD timing belts find application in a wide range of industries, including manufacturing, automation, robotics, packaging, and automotive, among others. They are used in various types of machinery and equipment where precise and high-torque power transmission is essential.

Overall, HTD timing belts are a popular choice when it comes to reliable and efficient power transmission in applications that require synchronization, torque capacity, and reduced backlash.

Here are the Best 5 HTD Timing Belt Factories which provide you with quality products.

1, ZZR PARTS

Website: https://www.zzr-parts.com/htd-timing-belt/

As a global leader in the industry, this company stands at the forefront as a premier supplier of high-performance belts suitable for a wide array of applications, including machinery, agricultural engineering, the automotive sector, household products, and more. With an extensive inventory comprising over 30,000 distinct SKUs readily available, they also offer customization options for sizes and materials to meet specific needs. Emphasizing global accessibility, they provide efficient shipping services worldwide.

2, Megadyne

Website: https://megadynegroup.com/en

Megadyne Group is a globally recognized leader in the development and production of power transmission belts, as well as associated components and comprehensive belt systems. With a strong commitment to serving both original equipment manufacturers and aftermarket distributors, Megadyne has established manufacturing facilities in Europe, North America, and Asia to cater to a wide array of applications.

Megadynes offers an extensive and diverse product portfolio, including thermoset and thermoplastic polyurethane belts, rubber timing and v-belts, pulleys, clamping plates, timing bars, and various complementary products. Megadyne’s offerings are not limited to standard solutions; they also provide customized products tailored to specific requirements. Megadyne Group’s global presence, dedication to quality, and ability to deliver a broad spectrum of power transmission solutions have solidified its reputation as a reliable partner for industries worldwide. Whether for industrial machinery, automotive applications, or other sectors, Megadyne’s products and expertise play a pivotal role in ensuring efficient and dependable power transmission systems.

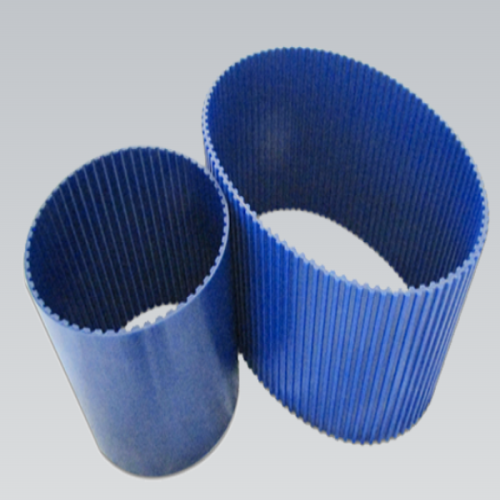

MEGAPOWER FC

HTD timing

3, Transmission Developments

Website: https://www.transdev.co.uk/

Transmission Developments has a rich history spanning over half a century, initially focusing on crafting precision timing pulleys. Throughout its journey, Transmission Developments has consistently striven to establish the utmost standards in power transmission. In its early stages, Transmission Developments visionary founder, Mr. Stuart Osborne, introduced the revolutionary polyurethane metric pitch “Synchroflex® Timing Belt” to a British industry that predominantly adhered to imperial measurements. This pioneering drive concept laid the groundwork for a company that has evolved into the largest independent, family-owned manufacturer and provider of transmission belting and associated products in the United Kingdom. Transmission Developments’ commitment to innovation and quality has propelled its growth, enabling it to become a prominent player in the field of power transmission, offering a comprehensive range of products and solutions to meet the diverse needs of its customers in the UK and beyond.

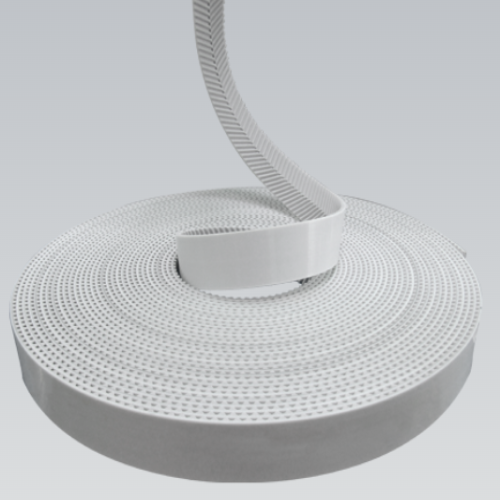

HTD Rubber Timing Belt

HTD CXP3M & CXP5M Rubber Timing Belts

4, B&B Manufacturing®

Website: https://www.bbman.com/

B&B Manufacturing® is a trusted name in the power transmission and precision mechanical component industries. Both distributors and original equipment manufacturers (OEM) rely on us to deliver the precise parts they need, precisely when they need them. Our expertise extends to standard, custom, and prototype synchronous drive applications, ensuring that our customers receive the ideal components at competitive prices, precisely when they need them. With a commitment to quality and reliability, B&B Manufacturing® is the go-to choice for those seeking top-notch solutions in power transmission and precision mechanical components.

5, ContiTech

Website: https://www.continental-industry.com/

ContiTech stands as a global industrial specialist, catering to a diverse range of industries including machine and plant engineering, mining, agriculture, and automotive. Boasting approximately 46,000 employees, ContiTech leverages its expertise in development and materials to create innovative products and systems. These solutions encompass rubber, polyamide, metal, textile, and electronic components, all complemented by individualized services. ContiTech goes beyond its origins as a rubber product manufacturer, also offering functional and design-oriented living solutions. ContiTech is committed to providing customer-friendly and environmentally-friendly solutions, exemplifying its dedication to progress and sustainability.

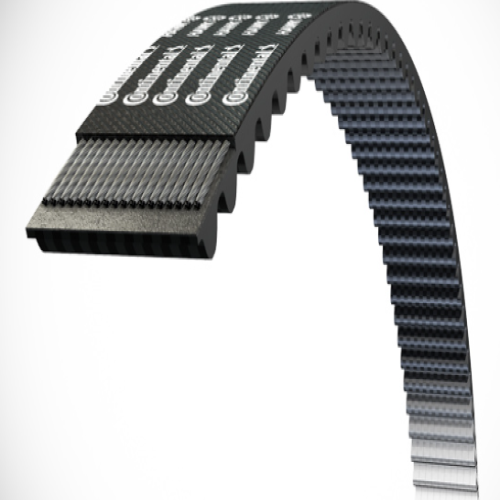

CONTI® HTD

CONTI® HAWK PD